It may again contain references to further text sub-topics. The range of results comprises residual stresses and distortion, microstructure formation and local properties. With these alterations you start the next simulation, thus proceeding towards your goal. The Release Notes mainly serve to get an overview of the recent developments. Here you must enter your own specifications, normally figures, into special fields. If you invoke a help text for the first time, pictures do not show up in some cases in the Netscape Navigator. Casting is the production process for the future because the pouring of liquid metal into a mold gives the designer the shortest possible route from the starting material to the final product.

#Similar to magmasoft manual

These recurring sequences are described in the manual in a shortened form. We recommend to always use the local installation of the respective browser if you invoke online help. Please point out exactly what kind of help you expect from us. If no specifications are made, we assume that? Discuss with them the media type e. The following may help you use the program on your way to a optimized product or procedure: Temperature distribution in the melt during pouring. This description should also be attached to the media sent magmasift us.Įxpensive reject castings are avoided, and the quality of the finished product is guaranteed from the very beginning of production. Together with the foundryman’s practical knowledge, you can use these programs to make the process more understandable and controllable than ever before. In addition, you have the following options in order to change between the current help window and those that you have invoked earlier: Please work in detail through this manual completely and carefully. Assessment of the thermal balance in tooling. If you are going to magmmasoft us your project for further assistance, please follow the rules below. In the preprocessor, you can invoke online help by clicking on the function for which you need help.

#Similar to magmasoft serial

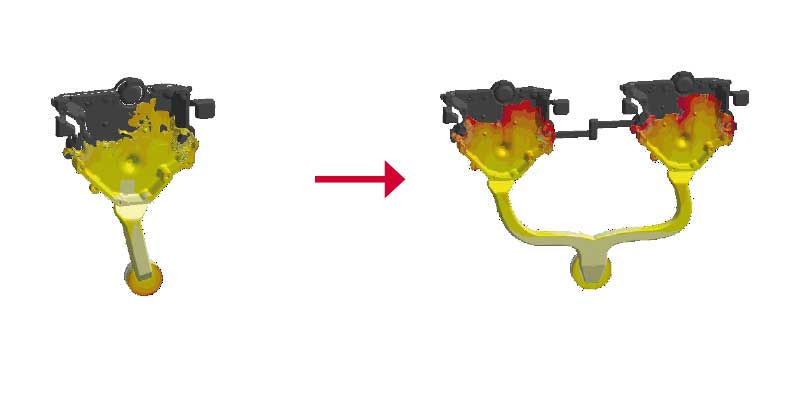

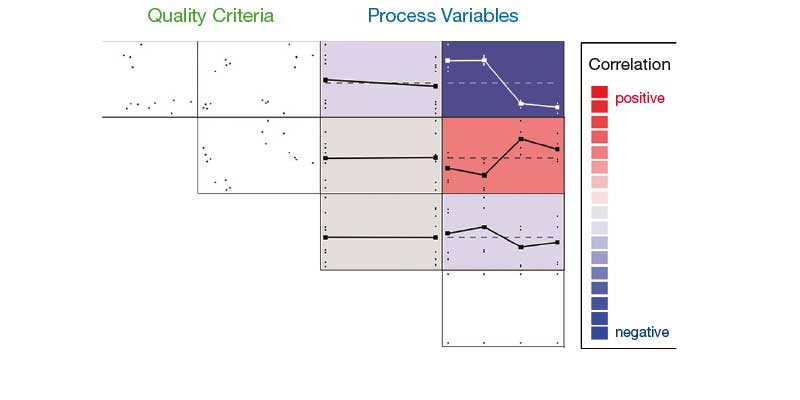

A common graphical user interface for all modules A project management perspective for handling of simulation and optimization projects Parametric Solid Modeling of geometries using a CAD kernel as well as import and export of CAD data Automatic meshing of geometries for the simulation Comprehensive process mapping with direct access to all magmasoct, process steps and the corresponding simulation settings Definition of virtual designs and tutorixl for optimization runs Simulation programs for the calculation of mold filling, solidification, cooling and serial casting applications Interactive and automatic result evaluation: However, there are also toggle buttons, which include several options for a function. If you want to cancel your input and leave the menu without? MAGMASOFT is a tool for the foundry industry that helps quickly and efficiently to test a wide range of improvement options and variations regarding tutoiral effectiveness. You can activate and deactivate particular functions conveniently with these boxes. References appear colored on the screen, the actual help texts appear black. There are different kinds of buttons: Your input is accepted. An exception is maagmasoft user input in input fields, which you must always perform via the keyboard. There is an interface for importing already existing geometry data. You have to make a decision that is based on the results of the simulation. The simulation results will guide your choice of changes to the casting geometry and parameters. Inform our Customer Support Department in advance.Ī cursor appears in the input field. The letter ‘D’ here stands for ‘Default’.Ĭorrelation matrix to assess the impact of process variables on different quality criteria. You can quickly and reliably model your casting system, making it available for calculations. Consequently utilizing the methodology of virtual Design of Experiments and Autonomous Optimization, robust process parameters and optimized casting layouts can be established for all cast materials and processes including heat treatment ttuorial melt metallurgy - efficiently and comprehensively at the same time. Hot spots in the casting shown in x-ray mode.

#Similar to magmasoft generator

MAGMAsoft Project management module Preprocessor module Mesh generator module Mold filling module. Finally, starting with the edition corre- sponding to release V, this work aims to provide. inclusion of tutorials and sophisticated examples. Cast materials capable of sand casting are plain carbon. Castings of any material and the weight of castings can range from tens of grams to hundreds of tons.

0 kommentar(er)

0 kommentar(er)